Alfa Laval sludge handling equipment boosts wastewater treatment capacity at Prosna, Poland

Belt and drum thickeners plus spiral heat exchangers: High capacity at small footprint

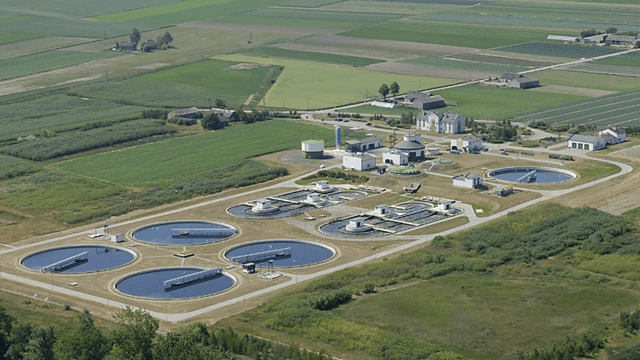

DATE 2023-11-28 The Municipality of Prosna has used Alfa Laval drum thickeners and spiral heat exchangers at its Kalisz municipal waste water treatment plant for more than 10 years. Needing to increase capacity they also invested in an Alfa Laval AS-H Belt Thickener in 2013 that meets all the company's requirements regarding capacity, space and necessary technological parameters.

The Municipality of Prosna has used Alfa Laval drum thickeners and spiral heat exchangers at its Kalisz municipal waste water treatment plant for more than 10 years. Needing to increase capacity they also invested in an Alfa Laval AS-H Belt Thickener in 2013 that meets all the company's requirements regarding capacity, space and necessary technological parameters.

Prosna Municipality entered a cooperation with Alfa Laval in 2000 when they installed in their Kalisz plant two Alfa Laval ALDRUM Drum Thickeners for the thickening of biological secondary sludge. They also installed one compact, highly efficient, self-cleaning Alfa Laval spiral heat exchanger for heating the sludge in the digester tank after the thickening and before dewatering.

During the following years, the equipment operated continuously without problems. However, in 2013 the drum thickeners could no longer keep up with the increasing volume of sludge from the 30,000 m3/d plant. Therefore Prosna consulted Alfa Laval and other suppliers looking for a solution.

Low polymer consumption and small footprint critical

The customer emphasized two critical selection criteria for the new thickening equipment. They wanted low polymer consumption and a unit that would fit into the existing building. As there was not enough space to install a third ALDRUM thickener, Alfa Laval offered Prosna a 1.5 metre wide Alfa Laval AS-H Belt Thickener, which would replace one of the two ALDRUM units.

Shorter and wider than a drum thickener

It was also possible to save space at the Kalisz plant by using a mixing valve that made it unnecessary to have a separate flocculation chamber and mixer. In terms of performance, the belt thickener has a consistent solids load across the filtration area which maximizes filtration throughput. Prosna followed Alfa Laval’s recommendation and chose the AS-H Belt Thickener. Besides fulfilling their main criteria it was also valued that they already had good contact with Alfa Laval and its local service center in with a good customer support team.It was possible to meet the limited space requirements because the belt thickener is shorter and wider than the drum thickener and has a smaller footprint. The belt thickener works on the principle of separating liquid from solids by gravity drainage through a porous filter belt. The drum thickener is basically a belt thickener that has been rolled up, where the slowly rotating drum filter separates the sludge, which remains in the drum, from the water phase that passes through the filter cloth. Both types provide gentle, efficient sludge thickening with high recovery, low power consumption and minimum operator intervention.

It was also possible to save space at the Kalisz plant by using a mixing valve that made it unnecessary to have a separate flocculation chamber and mixer. In terms of performance, the belt thickener has a consistent solids load across the filtration area which maximizes filtration throughput. Prosna followed Alfa Laval’s recommendation and chose the AS-H Belt Thickener. Besides fulfilling their main criteria it was also valued that they already had good contact with Alfa Laval and its local service center in with a good customer support team.It was possible to meet the limited space requirements because the belt thickener is shorter and wider than the drum thickener and has a smaller footprint. The belt thickener works on the principle of separating liquid from solids by gravity drainage through a porous filter belt. The drum thickener is basically a belt thickener that has been rolled up, where the slowly rotating drum filter separates the sludge, which remains in the drum, from the water phase that passes through the filter cloth. Both types provide gentle, efficient sludge thickening with high recovery, low power consumption and minimum operator intervention.

Fast installation

Alfa Laval's local sales office in Poland took care of the customer. The scope of supply included dismantling one of the two old drum thickeners, assembly of the new belt thickener with new inlet sludge pump and polymer pump, plus piping, control panel and start-up. The entire job was completed successfully in just seven days as required by the customer.

Satisfactory performance

The new Alfa Laval AS-H Belt Thickener has now been running for more than a year to the full satisfaction of Prosna. Their lab results confirm that the machine continues to fulfil all their technological parameters, such as a nominal design flow of 45 m3/h, a polymer consumption of 2-3 kg/t dry solids, a thickened sludge dry solids content of >6%, and an effluent quality of 200 mg/l suspended solids.

Prosna recommends Alfa Laval

Prosna’s Managing Director Jerzy Czuba and Operations Manager Slawomir Mickiewicz: “Delivery and commissioning of the new AS-H Belt Thickener were completed on time. We express our satisfaction with the cooperation with Alfa Laval and recommend the company as a good counterpart to perform equipment supply of sewage sludge treatment.”

Customer's voice

Delivery and commissioning of the new AS-H Belt Thickener were completed on time. We express our satisfaction with the cooperation with Alfa Laval and recommend the company as a good counterpart to perform equipment supply of sewage sludge treatment.

Prosna’s Managing Director Jerzy Czuba and Operations Manager Slawomir Mickiewicz

Products

For the thickening of biological secondary sludge:

For heating the sludge in the digester tank after the thickening and before dewatering:

Download the story

Reduce your environmental footprint with Alfa Laval's complete spectrum

Alfa Laval helps reduce the environmental footprint from water and waste streams, by maximizing reuse of water, by turning waste to value, and by minimizing energy consumption and waste. We offer a complete spectrum of equipment for wastewater treatment, filtration and sludge treatment that helps produce clean effluent for discharge or water reuse, recover heat and reduce the amount of sludge for disposal.