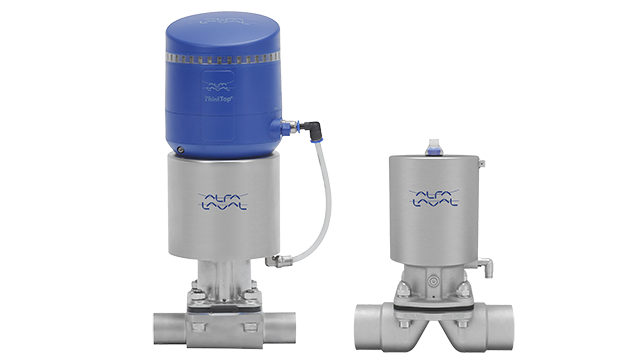

ThinkTop® V50

Alfa Laval ThinkTop V50 is a compact valve control unit for hygienic valves. It offers a single sensor solution and can be fitted with 0 or 1 solenoid valves, ensuring unmatched control of Alfa Laval DV-ST, Butterfly valves and Single seat valves for use in the dairy, food, beverage, brewery and pharmaceutical industries.

Intuitive, intelligent hygienic valve control

- Auto Setup, Live Setup and Flex Setup streamline and making setup quick and easy

- Smart, continuous monitoring through 24/7 self-diagnostics

- 360° LED status indication, easily visible from all angles

- Built-to-last: IP69K rating and vibration proof

- Savings of CIP liquid consumption on drain valve cleaning by up to 95% when using ASi and IO-link models

Control your hygienic valves with peace of mind using the Alfa Laval ThinkTop V50 valve control unit. A single sensor target control board handles all valve functions and communication. No adapters, special tools or cover screws are required. Non-crossing, colour-coded air hoses ensure straightforward connections. On top of this, enjoy a minimalist aesthetic housing made of composite material.

With only one sensor target and included adapter, ThinkTop V50 are easily retrofittable to existing Alfa Laval valves.

Alfa Laval ThinkTop®. Rethought.

Intuitive & Fast |

Smart & Adaptable |

Durable & Reliable |

Aesthetic Design |

Easy-to-access digital service and support

Access the service instruction manual and videos online or get the direct support you need using a convenient QR code located on the Alfa Laval ThinkTop housing.

The V-series fits all Alfa Laval hygienic valves. Select the right Alfa Laval ThinkTop valve control unit for your hygienic process needs based on the number of solenoid valves required. The ThinkTop V50 series fit on top of the Alfa Laval DV-ST, butterfly, single seat, SMP-BC and UMP CIP valves.

Exploit the power of IO-Link

Demand more from your valves with the Alfa Laval ThinkTop IO-Link. The ThinkTop IO-Link enhances communication between your hygienic valves and Industry 4.0 automation systems. The point-to-point IO-Link communication protocol connects sensors and actuators, regardless of fieldbus, to your automation systems. This makes meaningful real-time data easier to capture, store, analyze and act upon.

- Enhanced flexibility which lets you change data parameters and process data from a remote automation system

- More uptime and less cost due to 24/7 data monitoring and diagnostics

- Comprehensive overview of data for timely preventative maintenance and optimized performance

- Clearly visible LEDs with customizable colours and a 'wink' function that makes it easier to locate a valve from the factory floor

- Greater water and wastewater savings

Documents

Download

How it works

The Alfa Laval ThinkTop V50 valve control unit offers a single sensor solution for Diaphragm valves, Butterfly valves and Single seat valves and it can be fitted with 0 or 1 solenoid valves. The ThinkTop valve control unit converts the electrical PLC output signals into mechanical energy to energize or de-energize the air-operated valve, using the physical sensor target mounted on the valve stem.

Experience a seamless and speedy installation process with the Alfa Laval ThinkTop valve control unit's auto setup feature. To begin, just press the "Select" button, followed by the "Enter" button, and the setup sequence will initiate automatically. The process adapts according to the number of solenoid valves connected to the control unit. Additionally, if needed, you can perform a "Live setup" without disassembling the control head, enabling convenient remote configuration.

Pulse seat clean: cut CIP liquid consumption on drain valve cleaning by up to 95%

Drain valves comprise 20% of all valves in typical process plants. Imagine the water savings you can realize by adding the Alfa Laval ThinkTop pulse seat clean to your drain valve cleaning process.

In less than a second, an intensive jet of CIP liquid pulses through the gap between the valve house and valve seat, creating high turbulent flow and leaving the valve spotless. The result? Quick and effective cleaning, more uptime, and increased end-product yields.

Discover a new generation of ThinkTop® valve control units

Want to learn how the evolutionary Alfa Laval ThinkTop V50 and V70 can improve production on your hygienic process lines? Faster and more intuitive. Smart and adaptable. Durable and reliable. More compact yet with a highly functional design. The Alfa Laval ThinkTop. Rethought.

Cut Clean-in-Place liquid costs by 90% with optimized valve cleaning process

Are you interested to reduce consumption of CIP liquids? In this article, learn more about how you can achieve substantial water savings during the valve cleaning process – without compromising on product hygiene and safety.

You might also be interested in…

Food Logic

Alfa Laval's hygienic equipment combines high performance with gentle handling to preserve sensitive ingredients and keep up with the food industry trends. The equipment addresses four key challenges; supplying food products to consumers at a competitive price, getting the most from raw materials, reducing waste and emissions, and delivering safe and hygienic food products.

Close at Hand Catalogue

Alfa Laval's hygienic equipment product catalogue "Close at hand" includes product leaflets, performance curves, links to animations, brochures and lists for ordering purposes.

Ten top tips - Valves

near Newsletter

To keep you updated on important sustainability issues and opportunities in your industry and processes.