CPM

CPM valves maintain uniform inlet or outlet pressure in hygienic process lines for the dairy, food and beverage industries. These regulating valves provide accurate pressure control, safe and reliable performance and excellent cleanability.

Safe, effective pressure control

Alfa Laval Constant Pressure Modulating (CPM) valves are pneumatic regulating valves that maintain a constant inlet or outlet pressure in hygienic process lines. Thanks to a quick response diaphragm, these compact valves immediately react to any change in product pressure, adjusting position to keep the pressure at preset values.

Excellent valve cleanability

CPM valves feature a self-draining design and crevice-free, bowl-shaped valve body with welded valve seat to enable thorough cleaning, thus eliminating potential entrapment areas. The unique diaphragm with PTFE on the lower diaphragm also contributes to excellent cleanability.

Constant pressure valve range

Alfa Laval offers three types of CPM valves. Modular design enables the use of different plug sizes and different flow rates between 0.5 and 110 m3/h provide great operational flexibility.

Upon request, some CPM valves can be provided as ATEX-approved valves (group 2 category 3 D&G applications) for use in potentially explosive areas.

For more information, please refer to How it works and Documentation.

Compliance with most hygienic standards

Alfa Laval CPM valves meet most standards requested in the dairy, food and beverage, and personal care industries. Please refer to Documentation for more information.

Aseptic version

Designed to maintain a constant pressure at the valve inlet or outlet, using different plug sizes and different Kv values.

The diaphragm in the valve enables it under aseptic conditions to react effectively to any changes in product pressure by shifting position against a constant air pressure.

The CPM valve is often used upstream of aseptic filling and bottling machines.

Product Benefits

- Safe, effective pressure control

- Self-draining design

- Excellent valve cleanability

Channel Partners

Alfa Laval products are available through our channel partner network. Our partners provide product expertise and excellent service, with the goal to help you purchase the right product for your application.

Product catalogue

How it works

Construction

There are two different types of construction for Alfa Laval Constant Pressure Modulating valves.

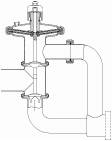

The CPMI-2 and CPMO-2 valves consist of a valve body with valve seat, cover, a valve plug with a special diaphragm and a clamp. The diaphragm consists of two flexible EPDM diaphragms supported by 12 stainless steel sectors in between them. The cover and the valve body are clamped together. The valve body and the seat are welded together.

The CPM-I-D60 consists of a CPMI-2 valve with additional piping.

Operating principle

The CPMI-2, CPMO-2 and CPM-I-D60 valves are controlled remotely by means of compressed air. The valves operate without a transmitter in the product line and only require a pressure-regulating valve for the compressed air and a pressure gauge in the product line (see below).

Where modulating back pressure is required (i.e., to maintain a fixed flow in and out of the CPM valve), the air supply to the valve can be provided by an I/P converter (typically 3-15 psi) and a booster valve. The product pressure dictates the pressure ratio of the booster valve.

A diaphragm reacts immediately to any alteration of the product pressure and changes position so that the preset pressure is maintained.

Inlet side: The Constant Pressure Modulating Inlet (CPMI-2) valves and the Constant Pressure Modulating Inlet D60 (CPM-I-D60) valves maintain constant pressure in the process line at the inlet side of the valve. CPMI-2 and CPM-I-D60 open when product pressure increases and close when product pressure decreases. These are often installed downstream from separators and heat exchangers, and may also be used as overflow valves.

Outlet side: The Constant Pressure Modulating Outlet (CPMO-2) valves maintain constant pressure in the process line at the outlet side of the valve. CPMO-2 closes when product pressure increases and opens when product pressure decreases (see illustration below). It is often installed upstream from pasteurizers, separators and filler systems of filtration units.

Options

- Fittings in accordance with required standard

- Air pressure regulating valve kit, 0-8 bar

- Diaphragm in PTFE covered in EPDM or PTFE

- Seals in NBR, FPM or PTFE

- Air throttling valve for adjustment of regulating speed for the CPM-2 valve

- Booster for product pressure exceeding the available air pressure (Product pressure = 1.8 x air pressure)

- 3A version available on request for CPMI-2 and CPMO-2 valves only

Constant-Pressure Modulating Inlet Valve

Constant-Pressure Modulating Outlet Valve

Constant-Pressure Modulating Inlet Valve D60