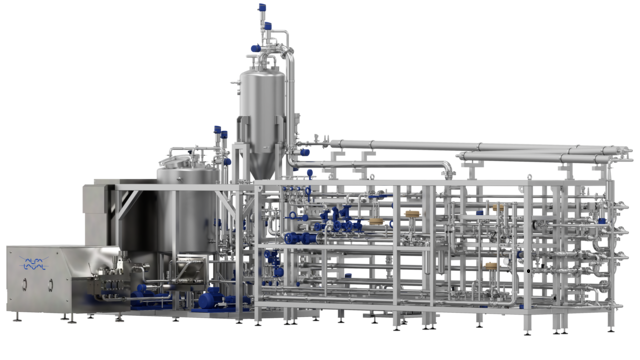

Alrox deaeration module under vacuum

Boost product quality, flavour and nutrients by removing dissolved gases from liquid food products with the Alfa Laval Alrox deaeration module under vacuum. Effectively deoxidize most product types, from single-strength juice to highly viscous products. It keeps heat transfer surfaces clean, prevents homogenizer cavitation, and promotes accurate volumetric filling. Integrate this pre-assembled, stand-alone, skid-mounted module with a pasteurizer or sterilizer to increase yield and shelf life.

Enhance product quality and stability by preventing liquid food product oxidation

- Keep liquid food products fresher longer while boosting flavour and nutritional value

- Optimize heat transfer efficiency by preventing fouling of heat transfer surfaces

- Achieve high filling accuracy by reducing oxygen levels

- Increase flexibility and production reliability by slowing process oxidation

- Improves retention of food flavour, colour, aroma, nutrients and stability

Count on the Alfa Laval Alrox deaeration module under vacuum to control food oxidation by removing free, dispersed and dissolved gases. This vacuum preserves product aroma, flavour, appearance and nutrients, such as ascorbic acid.

Unique features include a rotating spinner that creates consistently thick products by reducing the oxygen content of highly viscous products and an orange juice de-oiling unit. Capture and preserve aroma compounds with an optional aroma recovery condenser or recover make-up water by recirculating cleaned process water.

Choose Alrox deaeration module to maximize oxygen reduction in batch operation with versatile vacuum dryers or in continuous operation with in-line vacuum deaerators.

How does the Alfa Laval Alrox deaeration module under vacuum work?

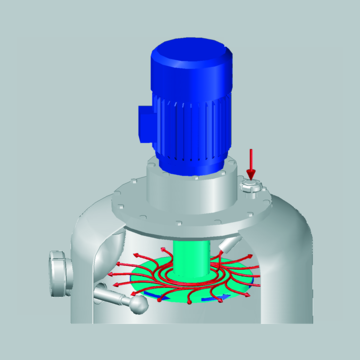

The incoming product, pre-heated to 65°-70°C, is then fed into the deaerator vessel. In the vessel, the vacuum reaches a level equivalent to a boiling point, generally 5° to 8°C below the pre-heating temperature. The temperature immediately drops when the product enters the unit. Under vacuum conditions, the product rigorously expands, and the dissolved air, along with product vapours, boils off. If desired, the vapours flow to a condenser, where they cool and recirculate with the product. A vacuum pump removes the boiled-off air from the vessel and non-condensable gases or certain off-flavours.

A liquid ring vacuum pump and a regulating valve maintain the vacuum. A level transmitter controls the product level, which drives the feed pump. The deaerated product is discharged through the bottom outlet and pumped out by a dedicated pump.

Equip the Alrox deaeration module with an integrated aroma recovery condenser, reducing aroma losses while maintaining product concentration. Vapours are condensed and can be reintroduced into the deaerated product if desired.

Products

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems