2018-11-10 Product news

New Alfa Laval Aseptic Mixproof Valve meets the needs of a growing market

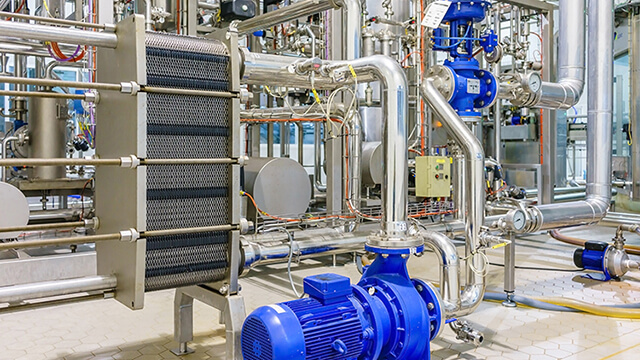

Alfa Laval is introducing an aseptic double-seat valve to its range of Alfa Laval mixproof valves. The new Alfa Laval Aseptic Mixproof Valve for sterile process applications is based on the same modular architecture as the well-proven aseptic version of the company’s Unique Single Seat Valve (SSV). More importantly, the Alfa Laval Aseptic Mixproof Valve reduces the total cost of ownership for dairy, food, beverage and other manufacturers by up to 45% compared to the leading aseptic double-seat mixproof valves.

The addition of the new Alfa Laval Aseptic Mixproof Valve to the Alfa Laval mixproof valve range provides manufacturers the convenience of a one-stopshop to meet all of their hygienic and aseptic valve requirements. This advanced double-seat mixproof valve ensures product safety through full protection against the intrusion of harmful microorganisms, even during unwanted pressure spikes. It also provides more uptime, exceptional hygiene, minimized product loss, and easy and cost-effective service.

“We have seen tremendous growth in demand for high-quality dairy, food and beverage products that have long shelf lives and clean labels,” says Anders Mose Lyhne, Product Portfolio Manager, Valves & Automation, Alfa Laval. “Our new Aseptic Mixproof Valve provides manufacturers with best-in-class valve flow characteristics during processing, cleaning and sterilization.”

The cleaning and sterilization flow characteristics, he adds, have been proven by CFD flow simulations. Initially, the Alfa Laval Aseptic Mixproof Valve range will include these valve sizes, which meet most manufacturer requirements: ISO 51 mm (2”), 63.5 mm (2.5”) and 76.1 mm (3“).

Low total cost of ownership

With the launch of the Alfa Laval Aseptic Mixproof Valve range, Alfa Laval is driving the total cost of ownership for aseptic valves to record lows. Using Alfa Laval’s aseptic double-seat valve instead of the leading brands can deliver a total cost savings of up to 45% to manufacturers using aseptic processing. Estimated savings are based on a comparison of capital expenses and maintenance costs of an aseptic 2½” valve over a five-year period if service is done onsite. If maintenance is done offsite by a third-party provider, competing technologies become even more expensive.

“Steel bellows and seal replacements are the most expensive maintenance costs for leading brands,” says Anders Lyhne. “Instead of steel bellows, the Alfa Laval Aseptic Mixproof Valve uses the same diaphragm with a PTFE face and reinforced EPDM backing which, over the past eight years, has been well-proven in our Alfa Laval Unique SSV Aseptic Valve. This drastically reduces the total cost of ownership of our double-seat valve, yet still ensures the hermetic seal required for sterile processing.”

Outstanding flexibility and modularity

Configure the Alfa Laval Aseptic Mixproof Valve to meet virtually any requirement. Choose a standard valve body and a tangential valve body or use two standard valve body types. Built on the same Alfa Laval Unique SSV platform, this aseptic double seat valve is easy to mount either in a horizontal or vertical position. There are three seat-lift versions, five steam valve types and a range of options for steam temperature monitoring.

Exceptional cleanability for more uptime

The optimized design of the Alfa Laval Aseptic Mixproof Valve makes cleaning and sterilization easier, thereby enabling more production uptime. With a highly flushable design and no domes in the product and steam areas, the valve provides better cleaning capabilities than other double-seat aseptic mixproof valves. What’s more, it complies with the strict requirements of the EHEDG and 3-A Sanitary Standards.

Ease of maintenance and parts replacement

Moreover, maintenance and parts replacement are also easy. Maintenance is made easy for those familiar with the Alfa Laval Unique SSV Aseptic Valve. The new Alfa Laval Aseptic Mixproof Valve follows the same maintenance routines. Most wear parts are interchangeable, making the valve maintenance friendly and streamlining parts replacement inventory.

To learn more about the Alfa Laval Aseptic Mixproof Valve, visit www.alfalaval.com/products/fluid-handling/valves/Double-seat-valves/aseptic-mixproof/

About Alfa Laval

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2017, posted annual sales of about SEK 35.3 billion (approx. 3.6 billion Euros). The company has about 16,400 employees.