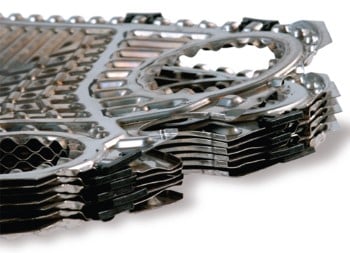

Reconditioning refers to services performed to the plates inside the gasketed plate heat exchanger. At Alfa Laval’s well-equipped service centers, our experts remove gaskets and scaling with specialized tools and chemicals. This prevents corrosion and creates an ideal surface for re-gasketing – without you having to handle the chemicals or waste. In addition, they thoroughly examine your heat exchangers, correcting any sealing problems or deformities. These services ensure your equipment continues to deliver high efficiency and optimal performance.

Full reconditioning is always necessary at a certain point. However, by using intermediate cleaning services it's possible to prolong the intervals between reconditioning.

Repair refers to services performed to the plate heat exchanger frame, and include inspection, refurbishment, replacement of connection linings, and replacement of bolts or other frame parts. While reconditioning plates must take place at one of our service centers, some frame repairs can be performed onsite. Please contact us for more information.

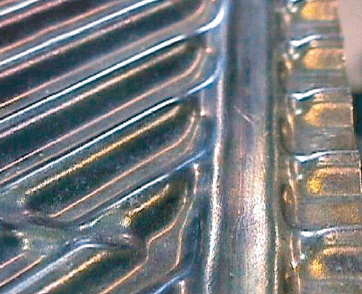

Liquid nitrogen doesn't harm plates unlike the field methods of using propane torches or rotating wire brushes

Chemical tanks that are heated and agitated provide a superior plate cleaning process compared to the water blasting and/or hand scrubbing with SS brushes in the field

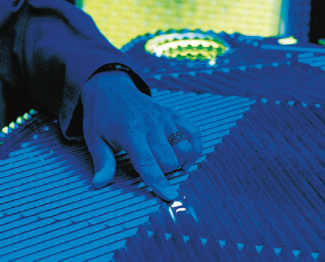

Each plate is dye penetrant inspected for cracks and pinholes, which is critical to ensure the regasketed plates are reusable. This is rarely performed in the field.

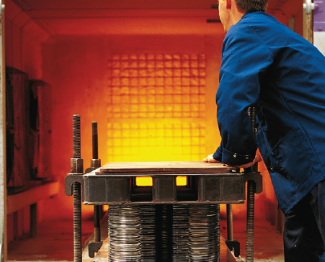

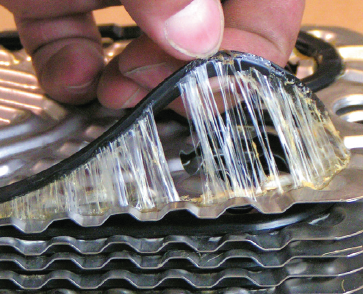

Our gaskets are bonded to the plates using a 2-part epoxy glue, placed in a curing skid and baked in the oven for 3 - 5 hours under compression. This epoxy is far superior to the rubber based contact cement used for field regasketing.

The plates are inspected to ensure the gaskets are properly positioned on the plates and arranged in the proper plate pack order to minimize the field installation time.

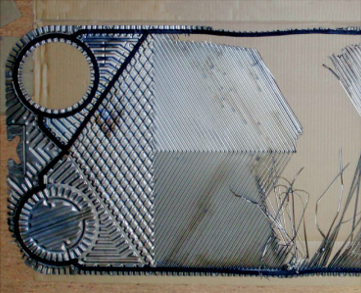

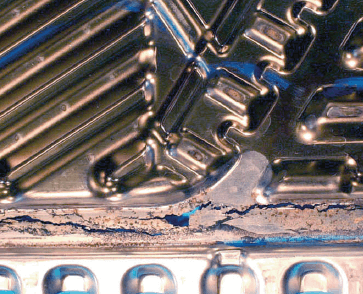

When old glue and gaskets are not completely removed, insufficient sealing is the result. This creates a high risk of leakage.

Chemical cleaning requires the right concentration, temperature and cleaning time. Otherwise, the plates can be destroyed.

Deformities can be difficult to see without experience and proper tools. Even small defects can cause production losses and safety risks.

The wrong gaskets or poor gluing can cause leakage. The wrong glue may even destroy the plate.

If standard glue is used on a frequently opened GPHE, the gaskets may fall off, making it necessary to re-gasket after opening.

Alfa Laval now offers a plate pack loaner program specifically designed for Marine customers, to help eliminate downtime of a ship's coolers or freshwater generators.

Not only does this program result in one less dry-docking project, but the program also ensures a ship always has a cooler on-board, virtually eliminating downtime.

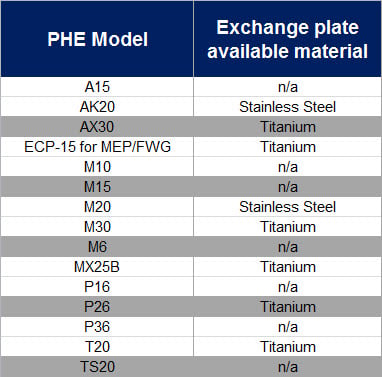

Alfa Laval reconditioning services for gasketed plate heat exchangers are organized into three packages: red, yellow and blue. This lets you choose the option that best meets your time, budget and application requirements.

Each package is handled by our expert service team and is supported by Alfa Laval’s more than 70 years of GPHE experience.

Alfa Laval’s blue reconditioning package is a fast cleaning service that can be used when the gaskets are undamaged. It is often used for interim service on clogged GPHEs that are normally reconditioned with our red package.

The package includes a general inspection and hydrojet cleaning, as well as a limited amount of gasket maintenance.

Used as a complement to our other packages, it offers a cost-effective way to boost GPHE performance.

Alfa Laval’s yellow reconditioning package is an economical option for GPHEs in gentler applications. It is generally used with GPHEs that do not operate at extreme temperatures or pressures, or with GPHEs in applications that do not involve aggressive chemicals or heavy fouling.

The package includes thorough cleaning and inspection, but excludes crack detection. Gaskets are remounted by glue-free means or with optimized rubber glue for general applications, and all PHEs reconditioned in this way receive a warranty from Alfa Laval.

The red reconditioning package is a full-service option for GPHEs in high-demand situations. It is generally used with GPHEs that are part of a crucial process, or with GPHEs in applications that involve aggressive chemicals and heavy fouling.

In addition to cleaning and inspection, the package includes crack detection and the remounting of gaskets by glue-free means or with heat- and chemical-resistant glue. All GPHEs reconditioned in this way receive a warranty from Alfa Laval.

Reconditioning packages for plate heat exchangers

360° Service Portfolio brochure